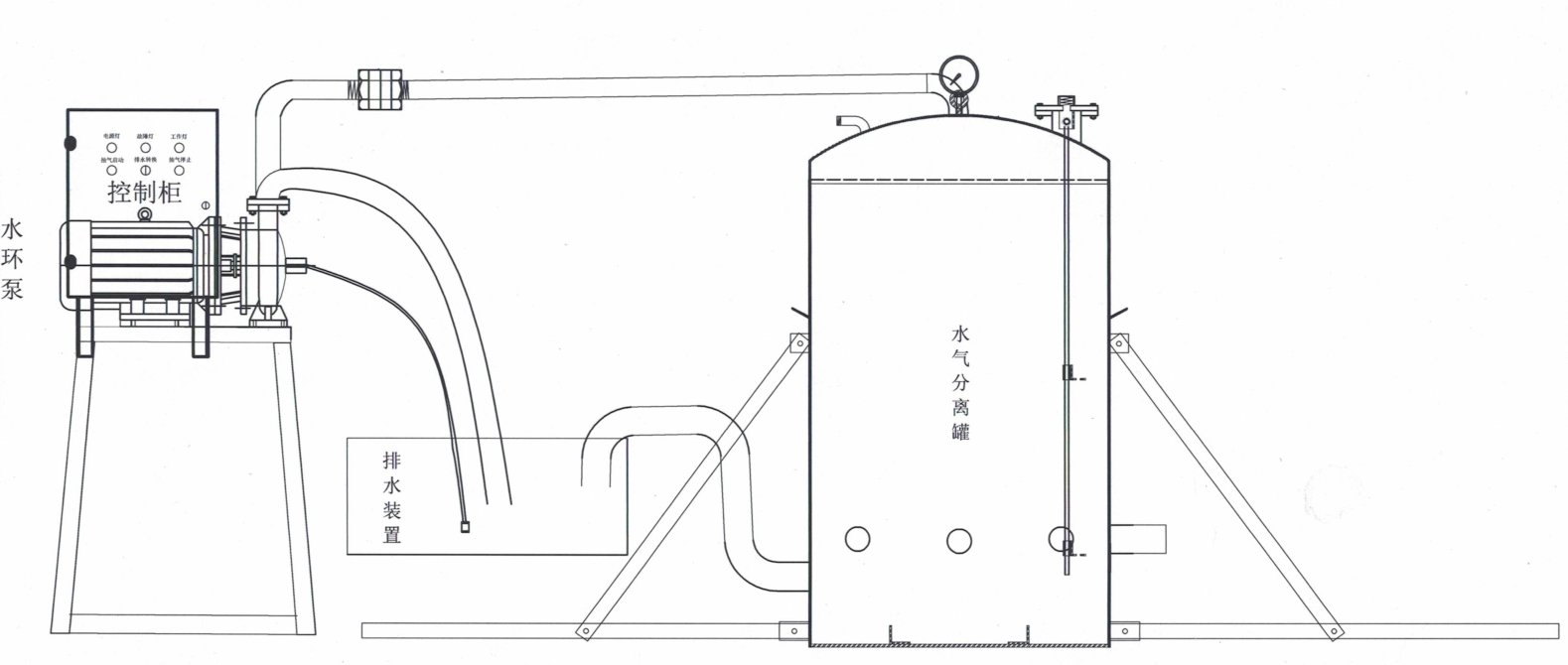

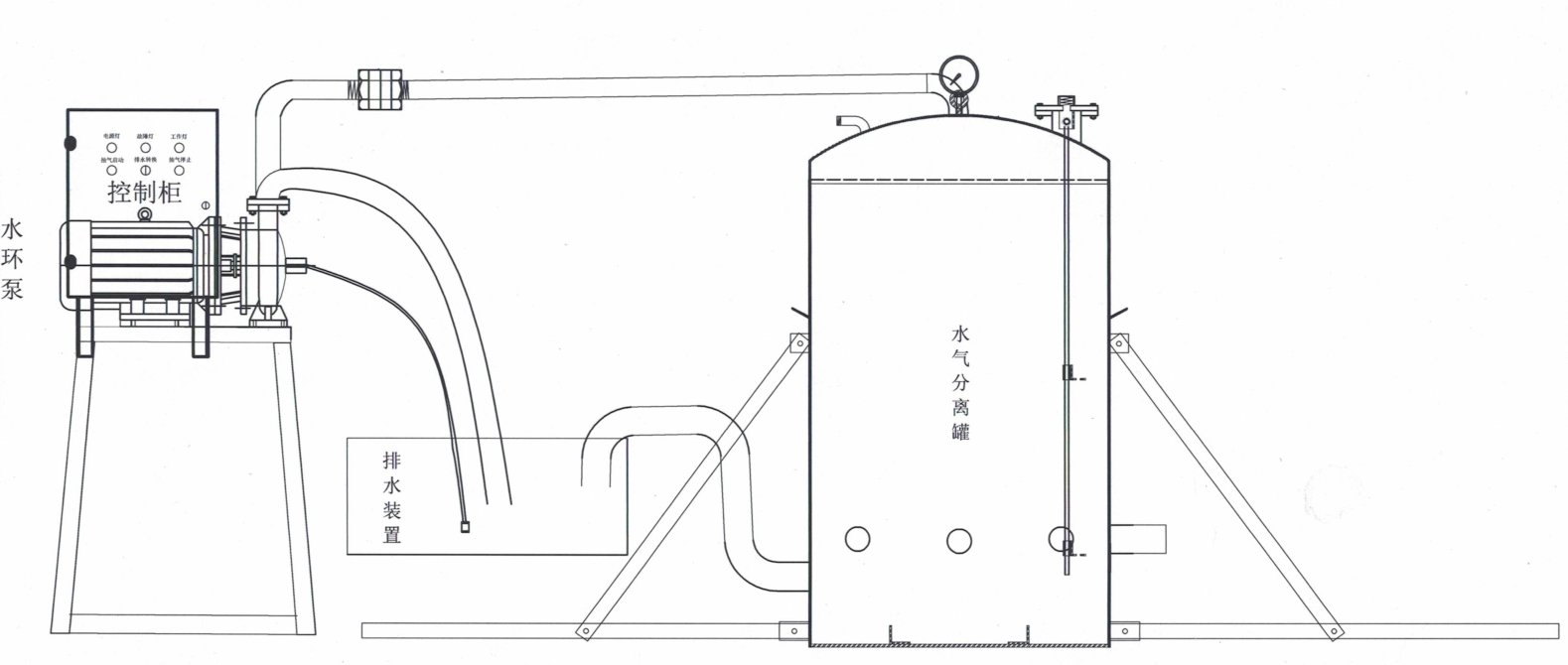

Vacuum Tank is the updated equipment to apply in the soil improvement projects. The vacuum tank is mainly composite by pumping lines, water & gas separation tank, and the electrical control. This structure is designed in accordance with the soil improvement feature, to isolate the water and gas from the ground.

The difference between Vacuum Tank & Vacuum Pump as below picture shown:

Item | Vacuum Tank | Vacuum Pump |

Soil Consolidation Time | Shorten | Normal |

Automation System | Electrical System | Manpower |

Working Hours | Shorten | Normal |

Water & Gas Drainage Rate | High | Normal |

Equipment Arrangement in 10000m2 | 2 Sets/ 10000m2 | 7.5kW/10 Sets/ 10000m2 |

Total Power for 10000m2 | 30kW | 75kW |

Performance

High Automation, Stable Construction, Steam Extraction Coefficient

Power Saving, Low Maintenance Cost

Simple Operation, Manpower and Material Saving

Vacuum Tank is the updated equipment to apply in the soil improvement projects. The vacuum tank is mainly composite by pumping lines, water & gas separation tank, and the electrical control. This structure is designed in accordance with the soil improvement feature, to isolate the water and gas from the ground.

The difference between Vacuum Tank & Vacuum Pump as below picture shown:

Item | Vacuum Tank | Vacuum Pump |

Soil Consolidation Time | Shorten | Normal |

Automation System | Electrical System | Manpower |

Working Hours | Shorten | Normal |

Water & Gas Drainage Rate | High | Normal |

Equipment Arrangement in 10000m2 | 2 Sets/ 10000m2 | 7.5kW/10 Sets/ 10000m2 |

Total Power for 10000m2 | 30kW | 75kW |

Performance

High Automation, Stable Construction, Steam Extraction Coefficient

Power Saving, Low Maintenance Cost

Simple Operation, Manpower and Material Saving

No. | Specification | Power Rate(kw) | Voltage (V) | Max Vacuum Level(Mpa) | Recommendation Application Area(㎡) | Max Inspiratory Capacity (m³/min) |

1 | HLSVTVT-1 | 5.5 | 380 | -0.096 | 2500-5000 | 3 |

2 | HLSVTVT-2 | 7.5 | 380 | -0.096 | 5000-7000 | 4 |

3 | HLSVTVT-3 | 55 | 380 | -0.096 | 40000-60000 | 35 |

4 | HLSVTVT-4 | 75 | 380 | -0.097 | 70000-100000 | 40 |

No. | Specification | Power Rate(kw) | Voltage (V) | Max Vacuum Level(Mpa) | Recommendation Application Area(㎡) | Max Inspiratory Capacity (m³/min) |

1 | HLSVTVT-1 | 5.5 | 380 | -0.096 | 2500-5000 | 3 |

2 | HLSVTVT-2 | 7.5 | 380 | -0.096 | 5000-7000 | 4 |

3 | HLSVTVT-3 | 55 | 380 | -0.096 | 40000-60000 | 35 |

4 | HLSVTVT-4 | 75 | 380 | -0.097 | 70000-100000 | 40 |

The equipment include the Pumping Lines,Water & Air Separation Tank, Water Drainage Device and Electrical

Apparatus Control System.

1. To connect the Vacuum Pumping Units with the top of the Vacuum Tank;

2. To connect the pipeline which under the Geo-membrane with the Vacuum Tank, and Water Drainage Device;

3. To create the negative pressure under the Geo-membrane by Vacuum Pre-loading Lines, to absorb water to the Vacuum Tank and drainage out by the drainage device.

The equipment include the Pumping Lines,Water & Air Separation Tank, Water Drainage Device and Electrical

Apparatus Control System.

1. To connect the Vacuum Pumping Units with the top of the Vacuum Tank;

2. To connect the pipeline which under the Geo-membrane with the Vacuum Tank, and Water Drainage Device;

3. To create the negative pressure under the Geo-membrane by Vacuum Pre-loading Lines, to absorb water to the Vacuum Tank and drainage out by the drainage device.

2024 IRAQ AL FAW PORT PVD CONSTRUCTION WORK

Project Background:The Padma Bridge is the largest project under construction in Bangladesh. The total investment is about 4.4 billion US dollars (about 29.2 billion yuan). The funds are all from Bangladesh ’s own funds; it is also the largest single bridge project undertaken overseas by Chinese com

Overview:NON-SAND VACUUM PRELOADING DRAINAGE METHOD is widely applied to accelerate the soil consolidation, which can apply in large area soft soil foundation treatment, especially to the dredging soil and super soft soil condition, It can greatly saving the construction period, it can replace the s

What is Soft & Weak FoundationSoft & Weak foundation refers to the foundation mainly composed of silt, silty soil, alluvial fill, miscellaneous fill or other highly compressible soil layers. This kind of foundation has high water content, low bearing capacity, poor stability, high compressibility, a

HLS Engineering the Ground Improvement Solution Provider. WE are contributed to provide Design, Construction, Machinery and Material to reinforce the soil.

What is Soft & Weak FoundationSoft & Weak foundation refers to the foundation mainly composed of silt, silty soil, alluvial fill, miscellaneous fill or other highly compressible soil layers. This kind of foundation has high water content, low bearing capacity, poor stability, high compressibility, a

What is Soft & Weak FoundationSoft & Weak foundation refers to the foundation mainly composed of silt, silty soil, alluvial fill, miscellaneous fill or other highly compressible soil layers. This kind of foundation has high water content, low bearing capacity, poor stability, high compressibility, a

What is Soft & Weak FoundationSoft & Weak foundation refers to the foundation mainly composed of silt, silty soil, alluvial fill, miscellaneous fill or other highly compressible soil layers. This kind of foundation has high water content, low bearing capacity, poor stability, high compressibility, a

Overview:Surcharge Preloading Method is widely apply in soft soil improvement projects, and the method will be Site Leveling + Sand Layer + PVD Installation + Drainage Channel Excavation. Performance:◎ Increase Bearing Capacity ◎ Increase Soil Consolidation ◎ Reduce different Settlement after Discha

Project Background:The project of Zhuhai Huihua Experimental School in Guangdong province is located in Pingsha Town, Gaolan Port Economic Zone, Zhuhai City. The project covers a total area of 32,000 square meters, with a total construction area of 37629 square meters, including 4515 square meters r

Project Background:On May 29, 2017, CCECC successfully signed the package 9 of the N8 highway expansion project. The project was obtained through the negotiation of tenders and was the government ’s own funds. The owner was the Bangladesh Army Engineering Office. The main project was the constructio

Project Background:This project is located in Bodu Akali County, Barisal Zone, southern city of Bangladesh, 210 kilometers away from the capital Dhaka and 160 kilometers away from Chittagong. A 2 × 660MW ultra-supercritical coal-fired power generating unit will be built, and the expansion conditions

Project Background:On November 2nd and 27th, 2017, CCCC-SHEC Third Highway Engineering Co., Ltd received the Phase 1 and Phase 2 bid winning notices for the repair and expansion of Highway 32 in Costa Rica. The two bids were merged into the first branch manager department after a study and decision